Hunan Guoci New Material Technology Co., Ltd.

Ceramic classifying wheels are core components of industrial classification equipment made from ceramic materials, primarily used for particle size separation of powders and particles. Compared to traditional metal classifying wheels, they exhibit significant advantages in wear resistance, corrosion resistance, and non-contamination due to their material properties, making them particularly suitable for industrial applications requiring high precision and high purity.

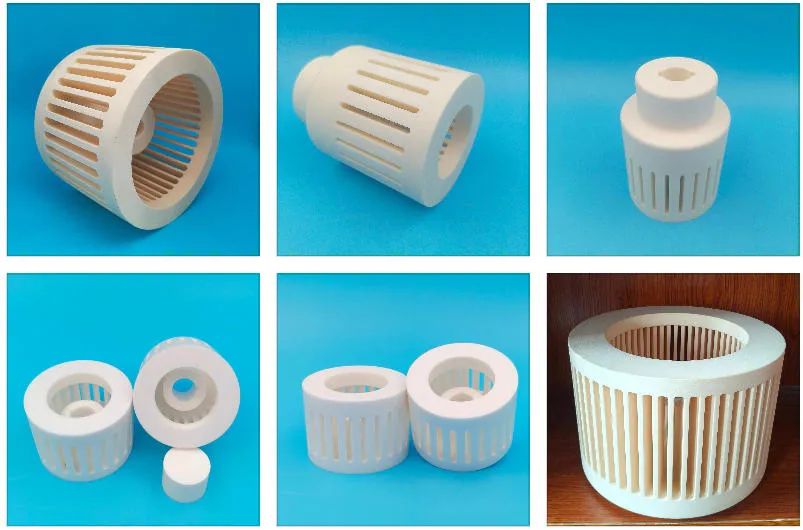

Alumina and zirconia ceramic grading wheels manufactured by Guoci Ceramics

2. Complete Isolation from Metal Contamination: As a pure ceramic component, the classifying wheel does not generate metal debris during high-speed operation, fundamentally avoiding metal contamination of the materials. This characteristic is crucial in fields with stringent purity requirements, such as lithium battery cathode materials, pharmaceuticals, food, and electronic materials.

3. Excellent corrosion resistance and chemical stability: Ceramic materials exhibit strong resistance to corrosive media such as acids and alkalis, maintaining stable performance even in harsh chemical environments and resisting chemical reactions or degradation.

4. Good thermal stability and resistance to deformation: Some advanced ceramics (such as silicon nitride ceramics) possess high thermal conductivity (approximately 30-40 W/m·K) and extremely low coefficient of thermal expansion (approximately 3.2 × 10⁻⁶/°C), enabling rapid dissipation of localized heat generated by high-speed rotation. This effectively prevents softening or deformation due to overheating, ensuring dimensional stability and operational accuracy under high-temperature conditions.

5. Smooth surface, less prone to material adhesion: The high surface smoothness of ceramics prevents material adhesion, facilitating cleaning, reducing the risk of material residue and cross-contamination, and improving production efficiency.

Main Application Areas of Ceramic Classifying Wheels

Ceramic classifying wheels, with their unique advantages, have been widely used in several industries with high requirements for equipment performance and material quality:

Currently, the mainstream ceramic grader materials include alumina ceramics (lower cost, good wear resistance), zirconia ceramics (higher toughness, superior wear resistance), and silicon nitride ceramics (excellent thermal conductivity, outstanding thermal shock resistance, suitable for extreme high-temperature environments).